Silver Jewelry Production Process

Unique craftsmanship and exquisite workmanship.Every piece of product is a manifestation of art.

Home / Jewelry Production Process

Silver Jewelry Production Process

From design to finished silver Jewelry, we pursue perfection at every step.

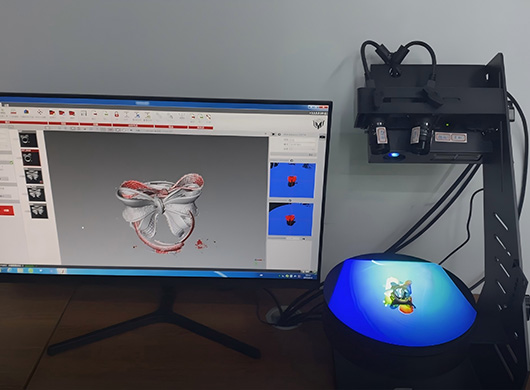

2. Making Mold

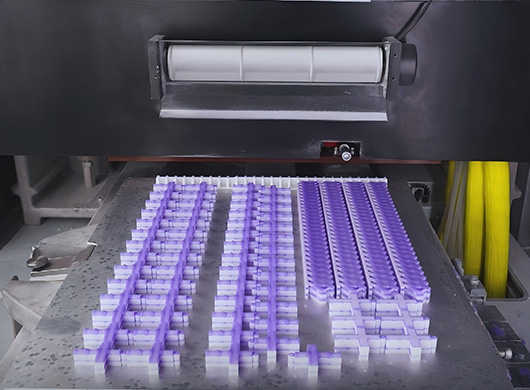

3. Infusing Wax

4. Stone Setting On Wax

5. Making Wax Tree

6. Pour In Silver Water

7. Cut Product

8. First Polishing

9. Second Polishing

10. Third Polishing

11. Plating

12. Finished Product

Silver Jewelry Materials and craftsmanship

We use international standard 999 silver materials and different ingredients according to other products. The silver content after smelting reaches more than 92.5%, making the product harder, tougher, and more resistant to oxidation.

Sterling Silver and its Master Alloys 925

| Alloy no. Silver | Alloys | Color | Karat | Application | Hardness | Casting Temperature ℃ | Advantage |

|---|---|---|---|---|---|---|---|

| O-AAG | H-PAT | White | 925Ag | C, R, C/S, L, S, W | 55 | 960-980 | A, D, HT, LH, LP, LR |

| 0-BAG | H-336 | White | 925Ag | C, R, C/S, L, S, W | 61 | 960-980 | A, EP, F, HT, LR, RC |

| 0-CAG | H-220 | White | 925Ag | C, R, C/S,L, S, W | 72 | 960-980 | D, HT, LH, LL |

| 0-DAG | H-330A | White | 925Ag | C,R, C/S,L,S | 65 | 960-980 | A, F, HT, LR, RC |

| 0-FAG | H-430 | White | 925Ag | C, R, C/S, L,S | 65 | 960-980 | A, F, HF, LR, RC |

| 0-HAG | H-555 | White | 925Ag | C,R, C/S, L,S | 64 | 960-1020 | HT, LR |

| O-JAG | H-633 | White | 925Ag | C, R, C/S, L, S, W | 60 | 960-1000 | A, D, F, HF, HT, LL |

| O-MAG | H-640 | White | 925Ag | C, C/S | 53 | 960-1000 | A, F, EP, HF, LR |

| O-SAG | H-550 | White | 925Ag | C, R, C/S, L, S, W | 68 | 960-1020 | A, EP, F, LP, RC, XH |

| O-ZAG | H-449 | White | 925Ag | C,R, C/S, L, S | 63 | 960-1000 | A, F, HF, LR, RC |

- A=Anti-tarnishing

- C=Casting

- C/S= Casting with stones

- D=Very ductile

- EP= Ease to polish

- F=Torch melting

- HF= High fluidity

- HT=Heat treatable

- L=Lamination

- LH = Less hard spot

- LL=Low melt loss

- LM = Low melting point

- LP= Less porosity

- LR=Less fire-scales

- P=Pass EN1811:2011

- NF=Nickel Free

- R= Hand-making

- RC=High recasting rate

- S=Stamping

- SC=Casting with silver

- W=Wiring

- XH = Extra hard

- XS=Extra soft

* Suggested temperature range for casting ± 25℃

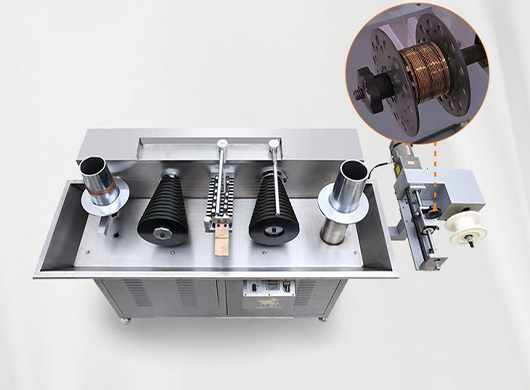

Complete Jewelry Processing Equipments

Use hard-core equipment to lay a solid quality foundation for exquisite silver jewelry.

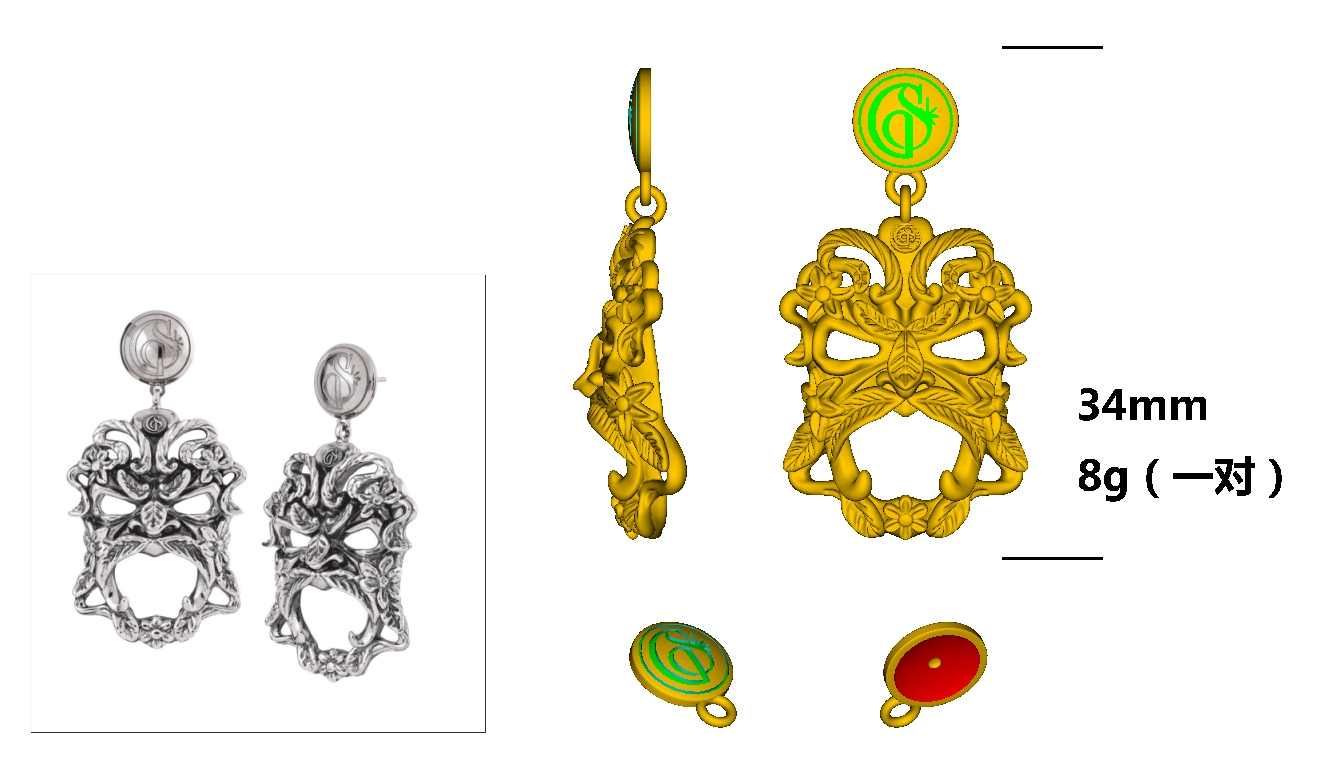

Silver Jewelry Customized Stories

Our customers are full of praise about every piece of product, Let's look at their feedback!

Customer Feedback:

Their products are of excellent quality and any inconvenience you may have with any product will be properly addressed.

A wholesale customer:

" I provided a picture and they restored it and made it close to 99% of the effect"

Customer Feedback:

Their products are of excellent quality and any inconvenience you may have with any product will be properly addressed.

Can I Help You?

Whether you are a jewelry wholesaler, a jewelry retailer, or just starting your own jewelry business, looking for a more cost-effective jewelry manufacturer, or looking for more jewelry styles, let us help you turn your dream into reality.

- Free Samples

- Products Catalogue

- Sample Book

- Sales Suggestions

Why AphroSilver

- All silver purity is over 92.5%

- 100% Satiafaction - 30 Days Return

- SGS Certificated Factory

- Nickle, Lead Free - EU EN 1811 & EN 12472

- Quick Quotation

- Tel

Please send your message to us

- Tel

- *Title

- *Content